Production

Orbital sawing up to DN200

CNC Tube bending

⌀06-115mm

CNC 4-roll plate bending machines Width 2000mm t=13mm

Orbital welding

Mig / Mag welding

Plasma welding

Pressure testing

Insulation work

Comprehensive manufacturing services for industry

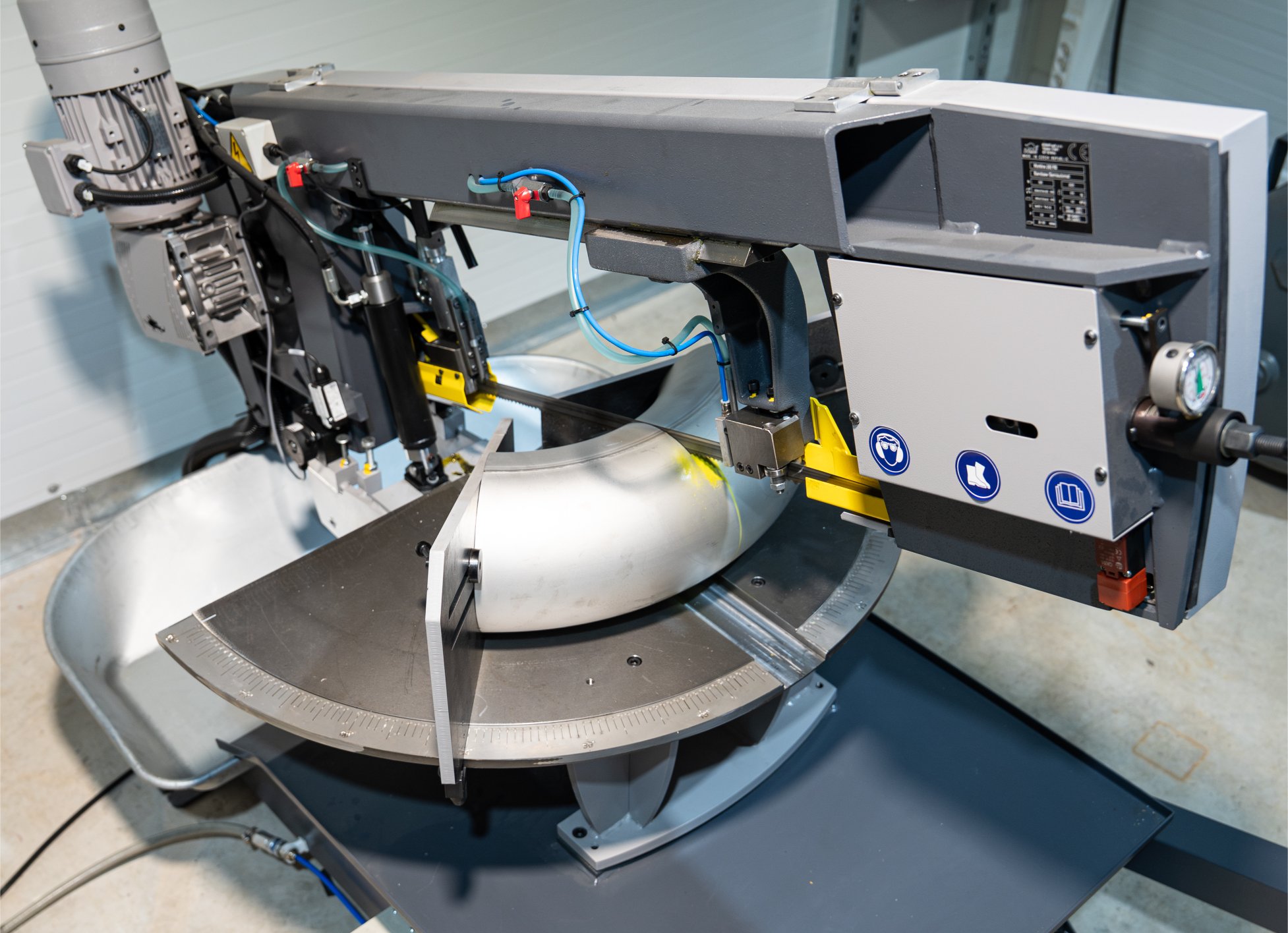

Sawing

Precise sawing of tube and tube bends

We offer tube sawing from Ø6 mm to Ø325 mm and tube bends up to 220 mm. We use modern equipment to ensure accurate sizing, a clean cut and a smooth finish.

Our service is suitable for both single items and larger series.

4-roll plate bending machines

4-roll plate bending machines with modern equipment

We offer 4-roll plate bending machineswith a modern 4-axis anvil equipped with CNC control. This allows for an accurate and repeatable result, as well as very precise mangling of variable shapes.

With a maximum width of 2 metres and a sheet thickness of up to 13 mm, the service is ideal for demanding industrial applications where dimensional accuracy, quality and flexibility are essential.

We carry out efficient mangling in both one-off and series production.

Tube end forming

Tube grooving and end forming

We offer Victaulic tube grooving services in the size range Ø21.3 – Ø325, using reliable equipment to ensure accurate and standard-compliant grooving for a variety of tube systems.

We also have cutting machines for shaping tube ends and flattening and shrinking machines to shape tube ends according to your requirements. Our range of services also includes cutting ring pre-cutting machines for compression fittings, ensuring reliable and high quality joints.

Our services are ideal for demanding industrial and tubing applications.

Bending of tubes and profiles

Bending of tubes and profiles with modern equipment

We offer tube and profile bending in the size range Ø6-114 mm. We have two CNC-controlled bending machines and one CNC-programmable roller bending machine, which enable us to achieve accurate and repeatable results even in demanding bending applications.

We have a very comprehensive tooling fleet, which allows us to carry out complex and demanding bending operations on different materials. In addition, our production is supported by smaller manual bending machines, which bring flexibility to individual and more specialised jobs.

We reliably carry out bending both as individual items and in series production.

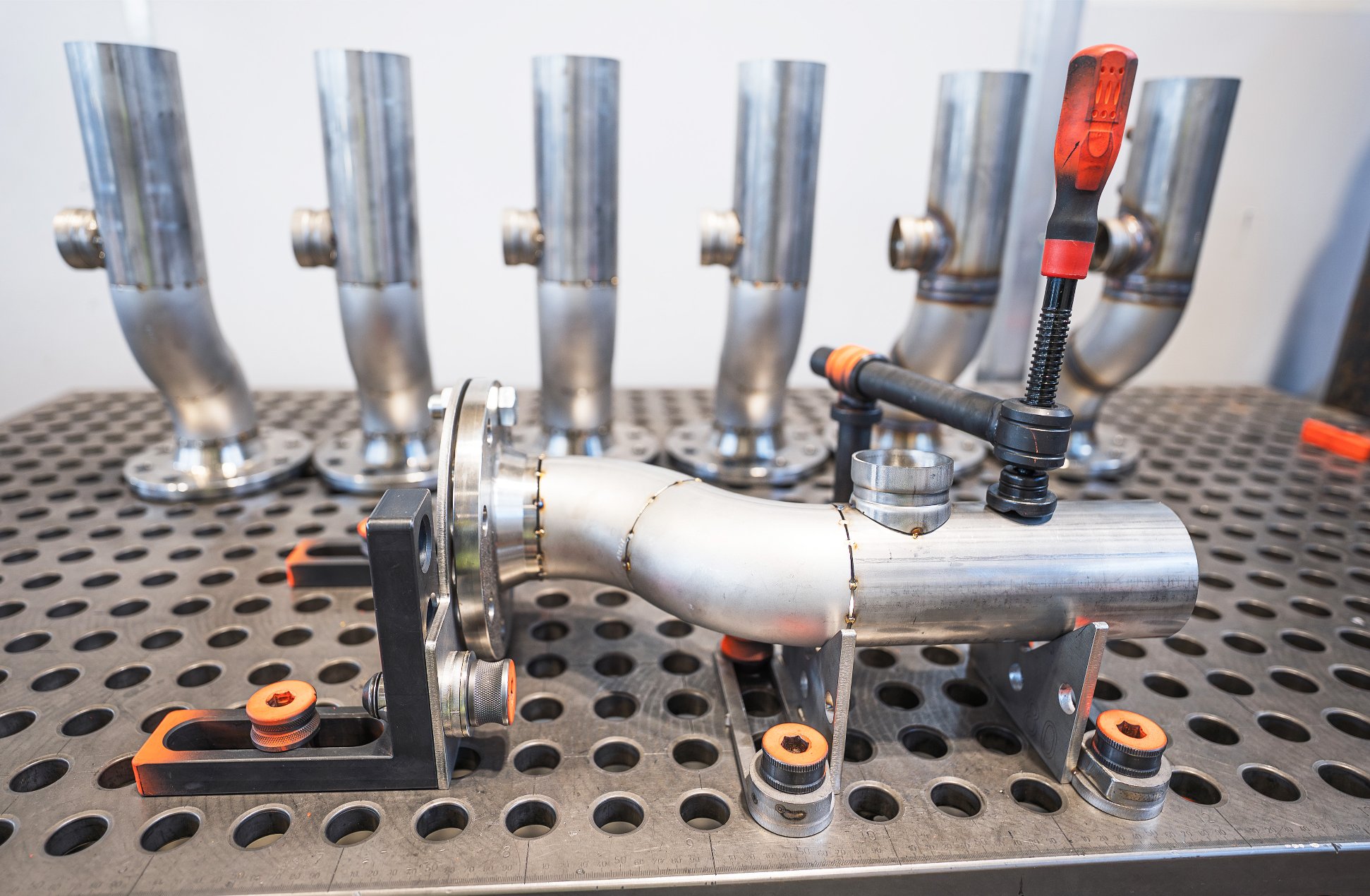

Assembly

Dimensionally accurate products with modern jigs

We have modern 3D jig tables that allow for highly accurate and repeatable configurations. This enables high-quality and efficient assembly work, even on demanding structures.

In addition, the handling of parts is supported by versatile machines for rotation and handling, which improve ergonomics, occupational safety and the quality of the end result throughout the manufacturing process.

We carry out assemblies reliably and with high quality.

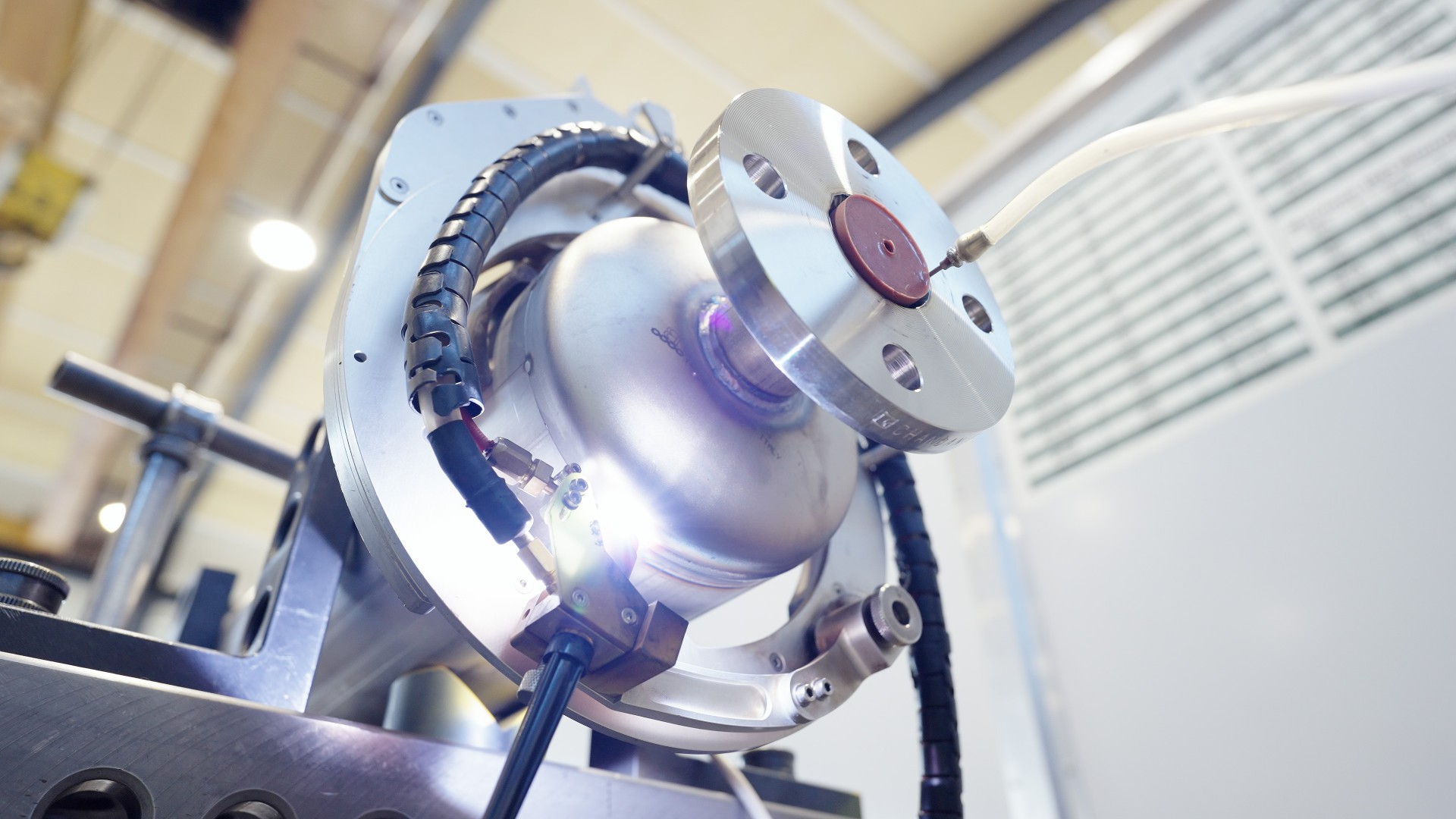

Welding

High-quality welding services

We offer professional TIG welding, MIG/MAG welding, orbital welding and plasma welding for demanding applications. Our skilled staff and modern equipment ensure strong, clean and accurate welds.

We have a comprehensive library of welding methods, enabling us to perform welds on a wide range of materials and requirements efficiently and reliably. In addition, we have mechanised welding processes with different types of rotators and welding booms, ensuring consistent quality and efficiency even in demanding serial production.

We also have Plasma longitudinal welding equipment, which allows us to weld the longitudinal lengths of tank casings accurately and efficiently.

Our services are ideal for industrial, process piping and special applications. We carry out both individual welding jobs and larger-scale projects reliably and on time.

Surface treatment according to customer needs

Finished products are always surface treated according to the customer’s requirements. We have an extensive network of reliable surface treatment companies, through which we can successfully:

- Powder coating and wet painting

- Pickling of bright steels

- Electrolytic polishing

Our service guarantees quality, durability and a clean finish for a variety of materials and products. We provide flexible surface treatments from single pieces to series production.

JP-Set Ltd’s production is based on modern machines, precise workmanship and continuous investment.

The latest addition to the production is the Faccin 4HEL-2122 4-roll plate bending machines, which enables the production of large and demanding tank structures with greater precision and speed.

We also have a large CNC-controlled machine base, efficient welding and assembly lines and a smooth material flow, which together ensure high capacity and a consistent end result. Watch the video to see our entire production process.